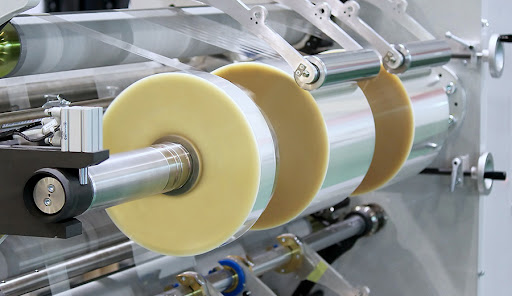

Choosing the right custom poly films for your products is essential for ensuring quality, durability, and presentation. Poly films, or polyethylene films, are versatile packaging materials widely used across various industries due to their flexibility, strength, and barrier properties. Whether you’re packaging food products, pharmaceuticals, or industrial goods, selecting the appropriate Custom poly films can significantly impact your product’s success.

Identify Your Product’s Needs:

Begin by understanding your product’s specific requirements. Consider factors such as product type, size, shape, weight, and fragility. For example, perishable food items may require poly films with excellent oxygen barrier properties to extend shelf life, while heavy industrial products might need thicker, Custom poly films for protection during shipping and handling.

Determine Desired Properties:

List down the essential properties your poly film must possess. This could include moisture resistance, UV protection, clarity for product visibility, heat sealability, or compatibility with printing techniques for branding and labeling. Prioritize these properties based on their importance to your product and market demands.

Consider Thickness and Gauge:

Poly films are available in different thicknesses or gauges, typically measured in mils or microns. Thicker films provide better puncture resistance and durability but may be less flexible. Consider the weight and fragility of your product when selecting the appropriate film thickness. For instance, delicate items may require thinner films to minimize potential damage during packaging and transportation.

Evaluate Barrier Properties:

Depending on your product’s sensitivity to external factors like moisture, oxygen, light, or odors, you may need poly films with specific barrier properties. For example, barrier films with oxygen scavengers are suitable for extending the shelf life of packaged food products, while light-blocking films help protect light-sensitive pharmaceuticals or chemicals.

Assess Environmental Impact:

In today’s environmentally conscious market, consider the environmental impact of your packaging materials. Look for eco-friendly options such as biodegradable or recyclable poly films made from sustainable sources. These options not only reduce environmental footprint but also appeal to environmentally conscious consumers.

Evaluate Cost and Budget:

Balancing performance with cost is crucial when selecting custom poly films. While high-performance films may come at a premium price, they can offer long-term benefits such as reduced product spoilage, improved brand perception, and lower overall packaging costs. Assess your budget constraints and weigh them against the desired features and benefits of the poly film.

Test and Validate:

Before committing to large-scale production, conduct thorough testing and validation of the selected poly film. Perform compatibility tests to ensure the film’s suitability with your packaging equipment and verify its performance under simulated storage and transportation conditions. Address any issues or concerns identified during testing before proceeding with full-scale production.